How to Navigate the New Reality of Manufacturing

The rundown

- Manufacturing executives’ largest challenge today is preservation – of both customer share and talent share

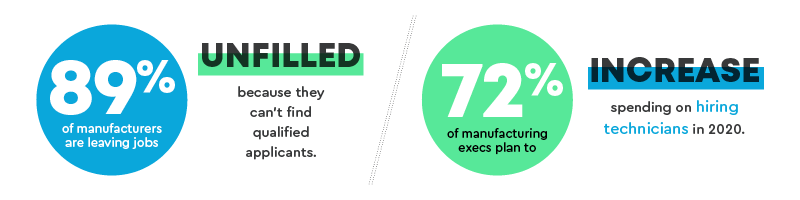

- 89% of manufacturers are leaving manufacturing jobs unfilled because they can’t find qualified applicants

- The combination of the ongoing COVID-19 pandemic and the manufacturing talent shortage is inspiring employers to get creative with their hiring initiatives

- To succeed today, you have to more effectively meet new (and changing) consumer demand by using technology

- In today’s economy, your current objective is clear – preserve, and ideally grow, your share of the talent pool and customer base

Table of contents

- The tipping point for industry transformation

- Make investments in talent acquisition and retention

- Implement tech to meet changing customer expectations

- About interviewstream

The tipping point for industry transformation

As the manufacturing sector enters a new age, meeting consumer demand while maintaining a competitive edge in the marketplace is proving harder than ever. The pandemic was the tipping point for an industry transformation that has been on the horizon for years, and now, research has found that manufacturing executives’ largest challenge today is preservation – of both customer share and talent share.

In response, workforces are being overhauled and manufacturing technology is advancing, changing the way that workers operate and raising the expectations of consumers. To compete in today’s market, you have to respond in kind – let’s dive into manufacturing trends and how to navigate the industry’s new reality.

Make investments in talent acquisition and retention

As far as hiring, manufacturing was initially one of the few sectors least impacted by the coronavirus. While some operations were stalled during the initial days and months of the outbreak, corporations like Tesla, GE, and Arconic are still competing for industry talent and they’re far from alone in their hunt for great workers – 89% of manufacturers are leaving jobs unfilled because they can’t find qualified applicants.

Source: “Infographic: The Pandemic’s Impact on the Manufacturing Industry“

In 2021, the manufacturing sector gained jobs, but by the end of the year, still hadn’t closed the gap (there was still a deficit of over 200,000 jobs). As a result, 72% of manufacturing execs plan to increase spending on hiring technicians.

The combination of COVID-19 and the manufacturing talent shortage is inspiring employers to get creative with their talent acquisition and hiring initiatives:

- Upskilling workers: As opposed to hunting for experienced and pricey talent, companies are targeting employees with high potential and opting to teach them valuable and job-specific skills in-house. This increases their potential labor pool but can be a costly proposition if you hire the wrong team members and have high voluntary turnover.

- Drive-thru alternatives: Staffing agencies have begun to coordinate drive-thru manufacturing job fairs and events so employers can connect with candidates and recent graduates without breaking social distancing recommendations.

- Remote video interviewing solutions: With video interviewing software, hiring professionals are able to interview 20% more top candidates from the safety of their own homes, resulting in a 58% reduction in time-to-offer.

Interested in our HR newsletter? Sign up below!

Sign up for our newsletter – we send out a newsletter email two to four times a year which includes HR trends, industry-relevant knowledge, and the latest interviewing tips for recruiters and candidates.

Implement tech to meet changing customer expectations

This crisis has also impacted the behaviors of consumer spending in every industry, driving many from traditional service offerings to digital alternatives. For example, consumers continue to invest in connected services and subscription businesses despite coronavirus – in fact, they’re spending more today than pre-pandemic.

The impact of this behavioral shift has been compounded by the fact that the pandemic illuminated gaps in supply chains for manufacturers of all sizes. With workers quarantined at home, execs were forced to reconsider their business strategies on the spot. The solution that most companies are turning to is investing in manufacturing technology and AI.

For years, automation has enabled major industry players to transition their service offerings to better fit the times. Look at Whirlpool. Despite being a traditional kitchen appliance manufacturer, their latest smart products integrate with applications, like their smart oven that pairs with recipe app Yummly and allows consumers to streamline meal-prep, temperature settings, and more.

And if that’s not convincing enough, consider DuPont. Since 1802, they’ve consistently remained on the cutting edge of innovation. Over the years, they’ve integrated new tech into their operations, staying on top of and ahead of manufacturing trends in the marketplace.

The company that once used bark from willow trees to manufacture dyes now makes a host of technologically-advanced products like Kevlar and Tyvek. Their agile and forward-thinking approach has led them to be a leading manufacturer of products that are staples in both the workplace and home.

To succeed today, you have to more effectively meet new (and changing) consumer demand by using manufacturing technology. Here’s how:

- Implement an inventory management tool: Keeping track of inventory is one of the most error-prone tasks for manufacturers – the global cost of understocking goods clocks in around $600 billion each year. And, consumer behaviors keep continuing the change – overstocking is becoming an increasingly expensive problem too. Inventory management software helps with sales planning, transportation scheduling, demand capacity management, and more.

- Leverage data insights: You have access to an unprecedented amount of data, but analyzing the information to uncover what actually matters is no small task. Implement a KPI software that collects and interprets internal and consumer data. Based on your business goals, the tech will compile the most important performance metrics in a dashboard so your team can transform the numbers into actionable steps. Examples of this data include asset utilization, demand forecasting, and maintenance cost per unit.

- Adopt a technician-centric approach: For many, operating without human workers is impossible. If that’s the case, invest in Internet of Things (IoT) tech that can help them better do their manufacturing jobs. When used correctly, IoT devices like smart factory equipment and wearable health monitors can improve productivity and boost employee retention – tackling two of the largest concerns facing manufacturers today. Beyond that, investing in your technicians will help to ensure safety while they’re on the job, reducing overall risk for you.

The manufacturing industry has always run at a fast pace, one currently accelerated by COVID-19. In today’s economy, your current objective is clear — preserve, and ideally grow, your share of the talent pool and customer base.

Don’t just work to navigate the current landscape — find ways to lead through it so that your company can be stronger than ever before. Start by meeting consumers and candidates where they’re at right now, by reevaluating your business plan, cutting unnecessary costs, and investing in an innovative future.

About interviewstream

interviewstream is an industry leading recruiting software company that helps you reach your top candidates more effectively. Our customers have completed over 3 million interviews using interview builder, interview on demand, interview scheduler, interview connect – and we’d love to help you as well. Talk to an expert today to learn how to get started.

Want a PDF version of this eBook?

Fill out the form below to get a PDF version of this eBook.

The interviewstream platform

Speak to an expert today to learn how our remote interviewing solutions make hiring more effective.

About interviewstream

As companies transition to remote work, we exist to help recruiters and hiring teams ask the right questions every time, screen candidates faster, make scheduling easier, and reach candidates everywhere. Using our remote interviewing platform, your team will have a complete view of the candidate in one location while also leveraging one of the leading platforms for online interviewing.